Laser cleaning

with laser company GmbH from Nürtingen

Laser Cleaning: How It Works and Areas of Application

Laser cleaning is one of the most fascinating technologies in modern surface treatment. It works almost like magic: dirt, rust, or paint simply disappear, while the underlying material remains completely intact.

Here is an overview of how it works, the areas of application, and a direct comparison to traditional sandblasting.

How does laser cleaning work?

The physical principle behind laser cleaning is called ablation. A laser source shoots extremely short, high-energy light pulses onto a surface.

- Absorption: The contamination (e.g., rust) absorbs the energy of the laser beam much more strongly than the base material (e.g., steel).

- Sudden heating: Due to the high energy density, the layer of dirt is heated so intensely within fractions of a microsecond that it evaporates or flakes off due to the resulting pressure.

- Selectivity: Since the carrier material reflects the laser light or dissipates the energy more effectively due to its thermal properties, the cleaning process stops exactly at the interface. The component itself remains cool and undamaged.

Summary of applications

Laser cleaning is extremely versatile and is used today in almost all industrial sectors:

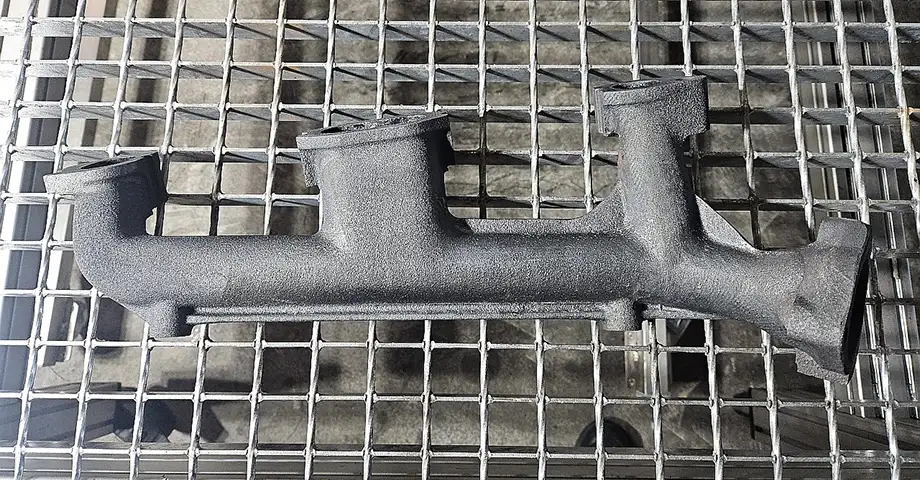

- Rust & paint removal: Ideal for the restoration of classic cars, bridges, or industrial components.

- Weld seam preparation: Removal of oxide layers and oils before welding for perfect results.

- Mold cleaning: In the tire or plastics industry, molds are cleaned while hot without leaving any residue and without changing the geometry of the mold.

- Facade cleaning: Gentle cleaning of historical monuments or facades to remove soot and environmental dirt.

- Degreasing: Residue-free removal of oils and lubricants in production.

- Fire damage restoration: Gentle removal of soot residues on almost all surfaces, including wood.

- Antiques: Removing paint, environmental dirt, and varnish from highly sensitive surfaces.